Equipment Advantages

-

Fully automatic operation with traveling filter cloth system

Even very thin filter cakes of 2-3 mm are automatically discharged and all filter cloth are washed simultaneously.

-

Effective and efficient cake washing

Top feeding port is adapted for excellent cake wash performance.

-

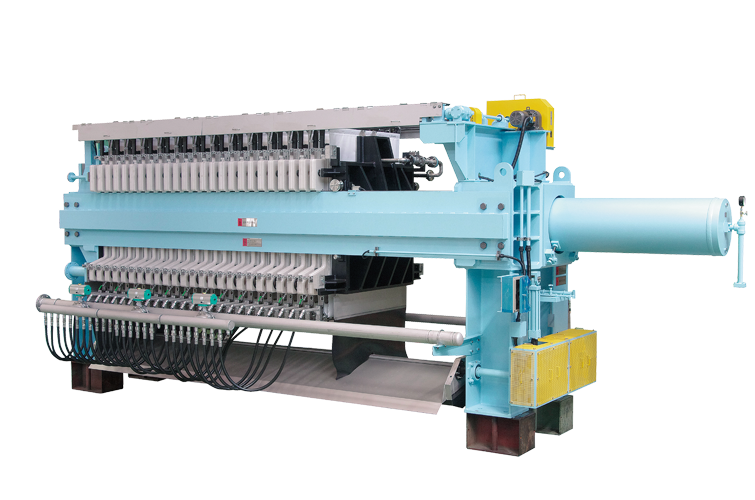

High performance and compact dewatering pressure filter

Simultaneous all filter plates open and close system saves the mechanical time and also generates the efficient cake discharge and cloth washing.

-

ISHIGAKI wishes to satisfy every customers requirement

Filtration area; from 8㎡ to 269㎡

Compression pressure; from 0.7MPa to 2.9MPa

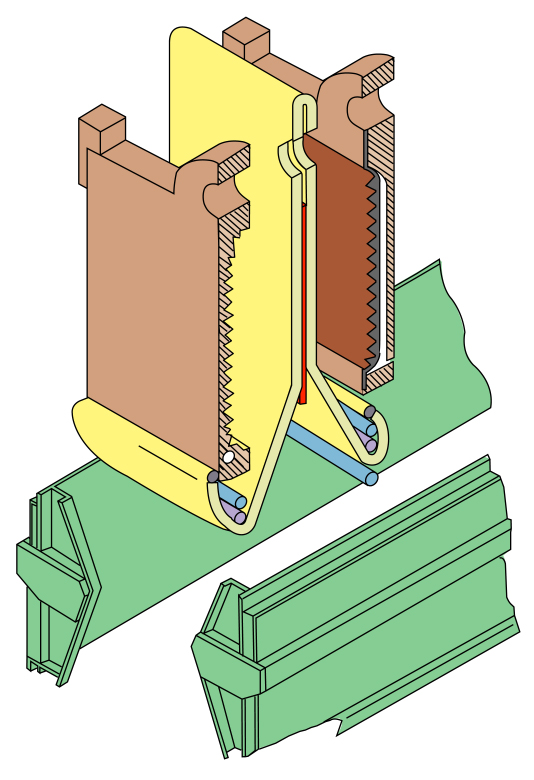

Mechanism

Filter Plate Pack Close

After activating the start switch, the hydraulic power pack pumps oil to the hydraulic cylinder which clamps all the filter plates together and forms each filtration chambers.

Filtration

Slurry is pumped via the feeding port to the filteration chambers. The solids remain and the filtrate passes through the filter cloth.

Compression

Pressurized water is jnjected behind the diaphragms. The filter cake is compressed and further dewatered.

Filter Plate Pack Open

After completion of filter cake compression process, the hydaulic pump operates automatically for driving cylinder and opening the filter plate pack.

Cake Discharge

When all the filter plates are opened, all the filter cloths containing discharged cake travel downwards and filter cake is discharged.

Filter Cloth Washing

After the filter cakes are discharged, the cake doors close and all the filter cloths are washed on the return travel.

Applications

|

|

Download Catalogue